Paint trucks operate in hazardous areas and you need to take precautions to ensure the safety of your employees and the facility. Every trusted Pyroban dealer provides explosion protection for lift trucks at a UK paint manufacturer. The manufacturer, which makes paints and specialist coatings at its 24/7 distribution center, operates in zone 2 hazardous areas that require specially adapted, Atex 2014/34/EU compliant lift trucks. Without these precautions, standard lift trucks operating in these areas can lead to explosions in the event of solvent vapor release.

The Components of the Explosion Protection System are:

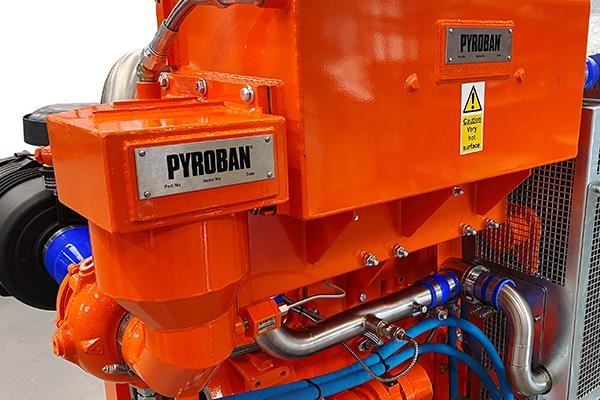

To meet the maintenance needs of the paint manufacturer, eight new electrically powered Aisle-Master AM20WHE articulated forklifts are supplied and converted by the Pyroban dealer for Zone 2 operation. These trucks feature Pyroban’s System 6000, an active detection system that incorporates gas detection to continuously monitor for the presence of a potentially explosive environment around each truck. In the event of a solvent vapor release, it will visually and audibly alert the driver and automatically shut the truck down, eliminating the risk of an explosion.

Additional trucks in the fleet, including the Yale ERP 16 VF four-wheel electric lift truck, the Yale M0103 order picker, and the Hako Scrubmaster B310R ride-on scrubber drier, have also been converted by our Pyroban dealer to the same high explosion-protection standards. These conversions include anti-static components to comply with EN 1755:2015, restricted breathing enclosures, stainless steel cladding of forks, and surface temperature cooling to ensure that the engine, motors, brakes, electrics, and other components remain below the auto-ignition temperatures of flammable materials.

Benefits of Explosion Protection

The use of explosion protection in hazardous areas not only keeps employees safe but also minimizes the risk of damage to the facility and equipment. The Pyroban System 6000 provides continuous monitoring and automatic shutdown in the event of a potential hazard, thus eliminating the risk of explosion. This, in turn, can help to ensure the longevity of the equipment and minimize the cost of maintenance and repairs.

Importance of Compliance with Hazardous Area Regulations

It’s important to note that the lift trucks at the UK paint manufacturer were compliant with Atex 2014/34/EU regulations for hazardous areas. These regulations are in place to ensure the safety of equipment and personnel in areas where flammable gasses, liquids, or dust may be present. By choosing lift trucks that are compliant with these regulations, the paint manufacturer can operate safely and legally. Additionally, being compliant with these regulations also ensures that the equipment is designed and constructed to minimize the risk of ignition and explosion.

Working with aPyroban dealer, the paint manufacturer was able to ensure that their lift trucks were not only compliant with hazardous area regulations, but also fully protected against potential explosions. The Pyroban dealer provided the necessary conversions to the lift trucks, including anti-static components, restricted breathing enclosures, etc. By working with a Pyroban dealer, the paint manufacturer was able to trust that the equipment they were using was fully compliant with hazardous area regulations and that their employees and facility were safe.

The Role of Fleet Management Systems:

Fleet management systems play an important role in ensuring the safety and efficiency of lift truck fleets. These systems provide real-time data on the location, status, and performance of each truck, allowing managers to optimize routes and schedules, improve productivity, and reduce downtime.

The Pyroban dealer allowed the paint manufacturer to have a fleet management system installed on the eight new electrically powered Aisle-Master AM20WHE articulated forklifts, which were supplied and converted for Zone 2 operation.

This enabled the manufacturer to have remote monitoring of the trucks’ performance, detect any issues before they lead to breakdowns, and schedule maintenance ahead of time.

In addition to improving safety and efficiency, fleet management systems can also provide data on fuel consumption and maintenance schedules, which can help to keep the trucks running at peak performance and minimize costs. Working with a Pyroban dealer, the paint manufacturer was not only able to ensure the safety of their employees and facility but also optimize the performance of their lift truck fleet and minimize costs.

Conclusion

The use of lift trucks in hazardous areas requires special precautions to ensure the safety of employees and the facility. Pyroban dealers ensure the safety of your employees and facility, and optimize the performance of your lift truck fleet, while also ensuring compliance with safety standards and regulations. If you are looking for a trusted dealer, have a look at Kanoo Machinery. We are a trusted dealer who can help you. Browse our website or get in touch with our team at km100.uae@kanoo.com.