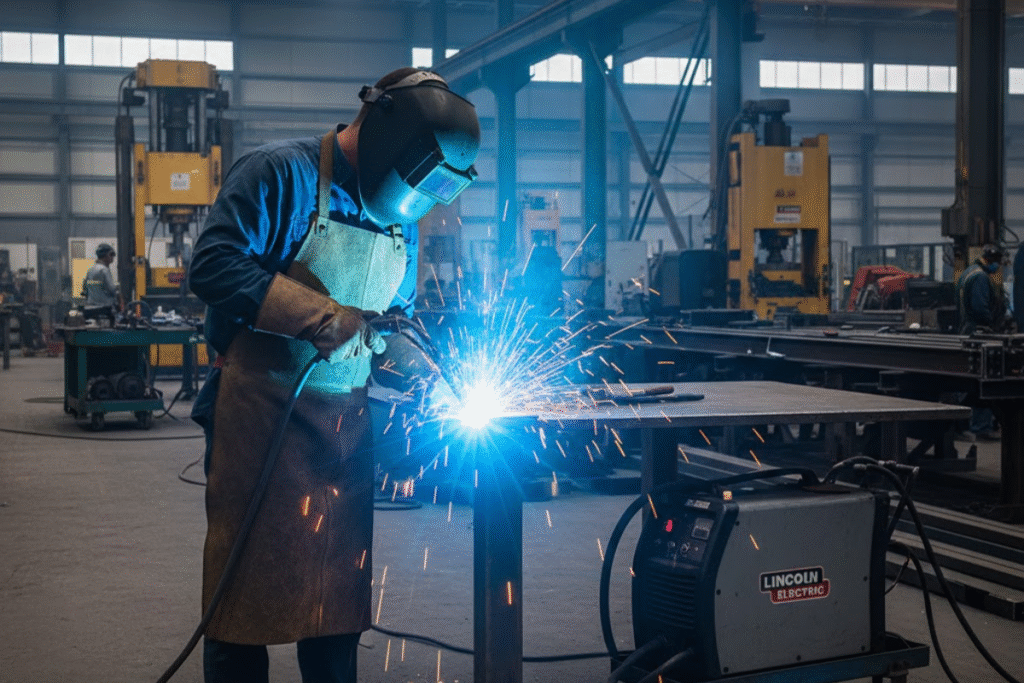

When it comes to precision, durability, and consistent welding results, the Lincoln Electric welding machine stands out as one of the most trusted choices worldwide. For businesses in the UAE, especially those involved in construction, fabrication, or manufacturing, choosing the right welding machine is not just a purchase — it’s an investment in efficiency and long-term performance. The UAE’s industrial sector requires tools that can withstand heavy workloads, variable weather conditions, and a diverse range of metal applications. Selecting the right model ensures that your operations remain smooth, productive, and cost-effective.

Understanding the Role of a Welding Machine in UAE Industries

Welding is the backbone of multiple industries across the UAE, from shipbuilding and oil refineries to construction and manufacturing. A reliable Lincoln Electric welding machine ensures that these industries maintain quality and precision while meeting project deadlines. The right welding equipment helps reduce downtime, improve weld quality, and enhance worker safety — three factors critical to industrial productivity in the region.

Since many UAE businesses operate in demanding environments, having a durable and efficient machine that performs well under pressure is essential. Lincoln’s range offers everything from portable units for light fabrication work to heavy-duty industrial systems designed for large-scale operations.

Factors to Consider When Choosing a Lincoln Welding Machine

1. Type of Welding Process

Before selecting a Lincoln Electric welding machine, consider which welding process your business uses most often.

- MIG (Metal Inert Gas) Welding is ideal for automotive, fabrication, and repair shops. It offers speed and clean welds, perfect for mild steel and aluminum.

- TIG (Tungsten Inert Gas) Welding is preferred for precision applications where appearance and accuracy matter, such as stainless steel fabrication.

- Stick Welding (SMAW) is best for outdoor and construction environments, known for its simplicity and ability to handle rusted or dirty metals.

Each Lincoln machine is built for specific applications, so choosing one that matches your welding process ensures better results and improved efficiency.

2. Power Requirements and Output

Different welding projects demand different power outputs. A compact Lincoln Electric welding machine designed for light-duty work may run efficiently on standard voltage, whereas industrial-grade models require higher amperage. In the UAE, where power stability is reliable, selecting a machine with a suitable duty cycle and adjustable settings helps optimize energy use while maintaining top performance.

3. Portability and Flexibility

For workshops or contractors handling multiple projects across different sites, portability is key. Some Lincoln models are compact and lightweight, making them easy to move between locations. Others are designed for fixed installations in large industrial setups. Selecting the correct configuration based on your operational needs ensures greater flexibility and convenience.

4. Material Type and Thickness

Not every machine handles all metals equally well. Consider the material thickness and type your team welds most often — whether it’s mild steel, aluminum, or stainless steel. A Lincoln Electric welding machine with adjustable current and wire speed controls will allow your operators to switch between materials with ease, ensuring precision and minimizing rework.

5. Durability and After-Sales Support

The UAE’s hot climate and dusty environments can take a toll on industrial equipment. Investing in a machine that offers superior build quality and robust protection ensures long-lasting performance. Lincoln Electric products are renowned for their robust construction and advanced cooling systems, making them well-suited for demanding working environments. Moreover, having access to reliable local support and spare parts through authorized distributors, such as Kanoo Machinery, guarantees minimal downtime and quick service.

Final Thoughts

Choosing the right Lincoln Electric welding machine for your UAE business comes down to understanding your operational needs, the type of welding work you perform, and the environments in which you operate. Lincoln’s advanced range offers solutions for every level — from small workshops to large-scale industrial operations.

For businesses in the UAE seeking genuine Lincoln products, Kanoo Machinery is your trusted partner. We offer a complete range of Lincoln Electric machines, parts, and after-sales support designed to meet your welding needs efficiently.

Get in touch with Kanoo Machinery today to explore the best Lincoln Electric welding machine options and elevate your welding operations with equipment built to last. Contact us at 800-KM100(56100).