Modern industries face increasing pressure to manage waste effectively. From manufacturing plants to recycling facilities, reducing volume, ensuring safe disposal, and recovering materials are all top priorities. This is where waste shredder machines step in. These machines play a crucial role in breaking down various types of waste into manageable sizes for further processing or disposal.

This article covers the most common types of shredder machines and their applications, helping you choose the right solution for your industrial needs.

1. Single Shaft Shredders

Single shaft shredders are best suited for materials that need to be reduced in size but not necessarily turned into very fine particles. They consist of a rotor and a hydraulic pusher system that presses material towards the cutting blades.

Applications:

- Plastic waste

- Wood pieces

- Light metals

- Electronic waste

These shredders offer precise control over output size and are ideal for facilities that need a moderate processing capacity. They are also energy-efficient and easy to maintain—making them a reliable waste shredder option for many mid-sized operations.

2. Double Shaft Shredders

Double shaft shredders are built for tougher materials. With two parallel rotors that cut in opposite directions, they are powerful machines used in heavy-duty environments.

Applications:

- Tyres

- Drums

- Construction debris

- Hazardous waste

The dual-shaft mechanism provides high torque at low speeds, reducing the risk of equipment wear and tear. These machines are a top choice for waste shredder needs in demanding industries like port operations, oil and gas, and large-scale construction.

3. Four Shaft Shredders

Designed for complex tasks, four shaft shredders offer superior output consistency. They come with two cutting shafts and two clearing shafts to achieve precise shredding and automatic discharge of shredded waste.

Applications:

- Confidential documents

- Medical waste

- E-scrap

- Industrial packaging

The four-shaft design ensures materials are not just shredded but thoroughly processed. These waste shredder machines are perfect for operations where output size must meet strict compliance or recycling standards.

4. Hammer Mill Shredders

These shredders use rotating hammers to smash materials against a heavy-duty grate. Instead of cutting, they pulverize waste into small pieces through impact.

Applications:

- Scrap metal

- Car bodies

- Steel drums

- White goods

Hammer mills are highly efficient for reducing bulky metal waste and recovering valuable materials. Though they consume more power than other types, their performance in heavy metal processing makes them an essential type of waste shredder in metal recycling facilities.

5. Granulators

Granulators are not always categorized as shredders, but they serve a similar purpose. They’re used after primary shredding to refine waste into very small granules.

Applications:

- Plastic pellets

- Film

- Soft rubber

- Post-industrial waste

These machines are often used in combination with other shredders. After materials are roughly shredded, granulators step in to prepare them for reuse or resale. For businesses dealing with high volumes of plastic waste, they offer an essential step in the wasteshredder process.

Choosing the Right Shredder for Your Operation

Selecting the right shredder depends on several factors:

- Type of Waste: Is it soft like plastic or hard like metal?

- Required Output Size: Do you need uniform particles or rough shredding?

- Throughput Volume: How much waste do you handle daily?

- Safety & Compliance: Are there industry regulations on waste processing?

- Maintenance & Cost: Can your team manage the upkeep and cost over time?

Final Thoughts

Waste shredding is no longer optional—it’s a business necessity. With increasing environmental standards and operational efficiency targets, investing in the right shredding solution can make a substantial difference.

Each shredder type offers unique benefits, and the best machine for your site depends on your specific application. Whether you’re processing plastics, metals, documents, or mixed waste, there’s a shredder tailored to the job.

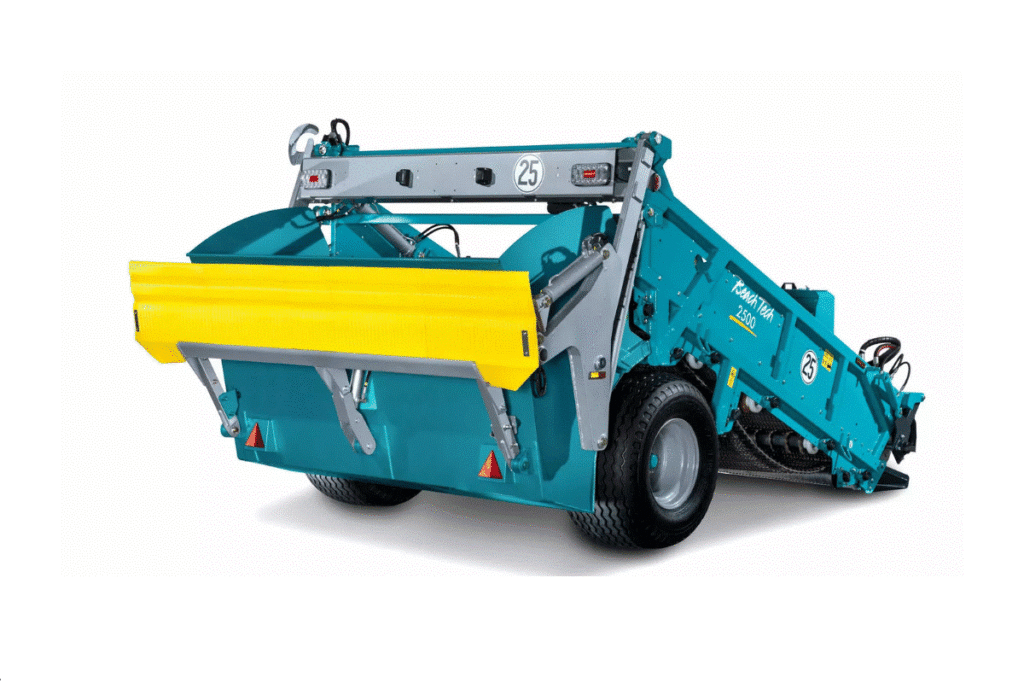

At Kanoo Machinery, we offer a complete range of industrial-grade waste shredder solutions built to meet the needs of modern businesses in the UAE. Our machines are engineered for performance, safety, and efficiency. Backed by expert support and quick service, we help you achieve your waste management goals with confidence.

Visit Kanoo Machinery’s Waste Shredder Solutions to explore your options or speak to our team for a custom recommendation at 800-KM100(56100).