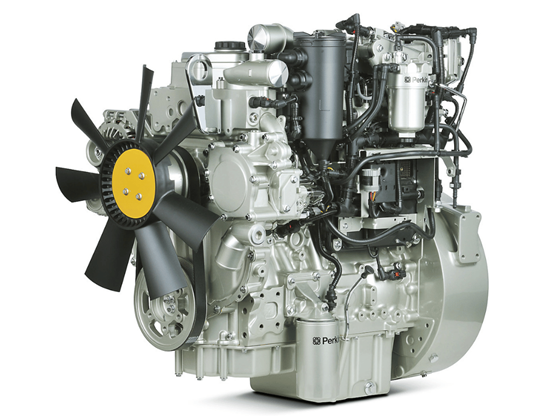

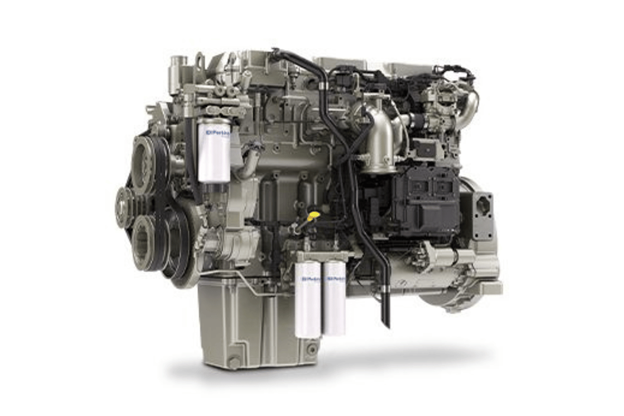

Perkins engines have a reputation for durability and reliability. They power various applications, from construction equipment to industrial machinery. However, even the most robust engines can face issues that lead to costly damage and downtime if not correctly maintained. This comprehensive guide will explore tips and practices to avoid expensive damage to Perkins engines and ensure their longevity. By following these guidelines, you can save time and money and avoid Perkins repair service for years.

Regular Inspection and Maintenance

Routine inspection and maintenance are paramount to prevent expensive damage. Regularly check for signs of leaks, unusual noises, and changes in performance. Addressing minor issues can prevent them from escalating into major problems. As Perkins recommends, engage in a comprehensive maintenance schedule that includes oil and filter changes, coolant checks, and air filter replacements.

Proper Lubrication

Lubrication is the lifeblood of any engine. Ensuring your Perkins engine is correctly lubricated is crucial for reducing friction and wear. Use high-quality lubricants recommended by Perkins to maintain optimal engine performance and extend its lifespan. Regularly check oil levels and adhere to the manufacturer’s guidelines for oil change intervals to avoid Perkins repair service.

Clean Air Intake and Exhaust Systems

Air intake and exhaust systems play a vital role in engine efficiency. A clogged air filter can restrict airflow and lead to reduced performance and fuel efficiency. Regularly clean or replace air filters to prevent dirt and debris from entering the engine. Additionally, inspect and maintain the exhaust system to prevent back pressure and exhaust leaks that could harm the engine.

Fuel Quality and System Maintenance

Quality fuel is essential for optimal engine operation and put off Perkins repair service for years. Ensure that you use clean, high-quality fuel that meets Perkins’ specifications. Regularly inspect the fuel system for leaks, clogs, and proper fuel injection. Taking care of the fuel system by cleaning the injectors and replacing fuel filters can prevent poor combustion and improve engine efficiency.

Cooling System Maintenance

The cooling system is critical for preventing engine overheating. Regularly check coolant levels and maintain the proper mixture recommended by Perkins. Inspect hoses, belts, and radiators to find leaks or damage. Adequate cooling system maintenance ensures your Perkins engine operates within the recommended temperature range and minimises the risk of costly overheating-related damage.

Addressing Issues Promptly

Even with diligent maintenance, issues can arise. It’s crucial to address any abnormalities promptly. Unusual noises, drops in performance, or warning lights should not be ignored. Timely diagnostics and repairs can prevent minor issues from evolving into major, costly problems.

Professional Perkins Repair Service

It’s best to rely on professionals specialising in Perkins engines for complex maintenance and repairs. A certified Perkins repair service provider, like Kanoo Machinery in Saudi Arabia, has the expertise and access to genuine Perkins parts to ensure proper diagnostics and repairs. Choosing an authorised service centre can save you time, money, and the hassle of dealing with unauthorised or substandard maintenance.

Conclusion

Preventing costly damage to Perkins engines requires a proactive approach to maintenance and a commitment to following manufacturer guidelines. Regular inspections, proper lubrication, clean air intake, quality fuel, and cooling system maintenance are all crucial steps. By investing in routine maintenance and addressing problems promptly, you can avoid expensive downtime and ensure the longevity of your Perkins engine. Kanoo Machinery is the optimal choice for reliable Perkins repair service and genuine parts. Our expertise and commitment to quality will keep your Perkins engine running smoothly and efficiently for years to come. Please browse our website to look at our products, or contact our team at ccmachinery@kanoo.com or our Toll free number, 920004017.